Conical rounding machines

Looking for a conical rounding machine for your premises? Check out our range! The conical rounders offered by Bagmasz allow for the precise shaping of dough pieces without disturbing their structure, resulting in a perfect appearance and stable parameters of baked goods. Bet on proven machines that are in operation in hundreds of bakeries across Poland and support business growth. Contact us and choose a rounder to suit your production needs.

Product description

Conical rounding machines for bakeries

Bagmasz offers professional dough cone rounders to meet the needs of bakeries with different production scales. Our machines are designed with intensive, multi-shift operation and the highest standards of hygiene in mind. Our conical rounders can operate as stand-alone machines or be an integral part of a complete production line. The ease of integration with other Bagmash equipment allows for flexible plant growth planning. This is particularly important for forward-thinking companies.

A variety of machine variants are available so that capacity, dimensions and functionality can be precisely matched to the real needs of the plant. We advise at every stage of the selection process, based on years of experience and hundreds of implementations.

Dough rounding machines - machine specifications

The conical rounder is an industrial machine designed for rounding previously divided dough pieces. This process takes place in a controlled and gentle manner, which preserves the dough structure and technological properties. This is crucial especially for demanding doughs such as rye or mixed doughs.

These machines can handle a wide range of dough types perfectly - from wheat to mixed to rye. Thanks to their adjustable operating parameters, conical rounders can be adapted to the weight of the pieces, the elasticity of the dough and the expected output. This flexibility significantly increases their versatility.

An essential part of the design is the cone and the working chutes, which are responsible for the correct shaping of the dough. Coating them with Teflon reduces sticking and eliminates the need for frequent cleaning, which contributes to smooth operation. The whole is enclosed in a robust stainless steel housing.

Bagmash dough rounders can operate continuously, making them ideal for high throughput plants. The stability and repeatability of operation are features that directly affect the quality of the final product.

Advantages of our conical rounding machines

The main advantage of the rounding machine is that it is gentle in the rounding, without disturbing the gluten structure of the dough. In addition, the use of the machines guarantees optimum rounding of the dough piece and 100% repeatability. The cone and troughs are coated with Teflon to prevent dough sticking, while the stainless steel housing ensures the durability of the machine.

Key advantages of Bagmasz conical rounding machines:

- the ability to work with almost any type of dough,

- high performance and stable operation,

- simple operation and easy maintenance,

- fault-free, robust design,

- wide possibilities of individual configuration.

Conical rounding machine - applications

Conical rounding machines are used wherever precision, repeatability and speed are important. They are most commonly used in bakeries producing bread, rolls and speciality breads. It is a process step that directly affects the quality of the final baked product.

These machines are suitable for both craft and industrial production. Thanks to adjustable parameters, it is possible to adapt the machine to short runs or large volumes. The flexibility of application makes them a versatile production tool.

The dough rounder can operate as a stand-alone station or be part of an automated line. In combination with weighing machines, proofing machines and Bagmash ovens, it forms a coherent, efficient bread production system.

Increasingly, conical rounding machines are also being used in plants developing their product range to include new types of products - including bakery products. They enable new recipes to be implemented quickly without the need for costly technological changes.

Conical rounding machines - types

Bagmasz offers both full-size conical rounding machines and compact versions. This allows each entrepreneur to select a machine that is ideally suited to the size of the plant and the planned output. This is particularly important when production space is limited.

The basic versions of the machines feature capacities of up to 2,400 pieces per hour. They are equipped with Teflon working elements, an adjustable flour sprinkler and the possibility of installing blowing or lubrication. Two loading points increase the ergonomics.

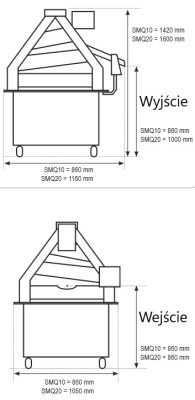

Small conical rounders are designed for billets weighing between 50 and 250 g. Despite their compact dimensions, they offer a capacity of more than 2,000 pieces per hour. The mobile design on wheels with brakes facilitates the organisation of the production area.

An additional advantage is that the machines can be retrofitted with an inverter, which makes it possible to work with difficult and quality doughs. Each conical rounding machine can be configured according to the investor's individual requirements.

Bagmasz - your bakery equipment supplier

Bagmasz is a company with a 30-year tradition, which for years has been supporting bakeries all over Poland in the selection and implementation of modern technological solutions. Thousands of customers have placed their trust in us, appreciating the quality of our equipment and our comprehensive service at every stage of cooperation.

When you choose us, you not only receive conical rounding machines, but also full technical support, warranty and post-warranty service and all the necessary documentation. In the event of repairs, we make replacement machines available, allowing you to maintain production continuity.

We supply entire production lines - from rounding machines to dividers, bread linesThe company's production facilities include conveyor belts, through to bowl tipplers. Each project is implemented individually, taking into account the needs of the plant.

On request, we also carry out trials of the equipment directly at the customer's site, conducted by experienced specialists. Contact us - we will be happy to answer all your questions and help you choose the best solution for your bakery.