Tippers for beater boilers

Product description

Sugar beater boiler tipplers - safety and efficiency at work

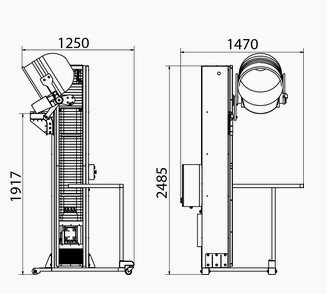

We offer tipplers for confectionery beater boilers, which are designed to increase productivity and safety in professional confectionery, bakery and food laboratories.

These devices significantly improve the process of working with confectionery mixes, enabling lifting and turning the beater boiler to a specific height without the use of physical force. Thanks to the automatic lifting and rotating mechanism of the boiler, the mass can be precisely poured into moulds, containers or subsequent production stages, eliminating the risk of spillage or loss of raw material.

Because the whole process is carried out mechanically, the tippler significantly increases occupational safety by reducing the physical strain on the operator and minimising the risk of injury. The unit also complies with health and safety regulations, which is particularly important in industrial and food production environments.

Tipper operation is intuitive and convenient - all functions are controlled via the control panel, which allows precise setting of the lifting height, boiler rotation speed and other operating parameters to suit the user's needs and the type of mass to be processed.

Advantages of tippers for confectionery beater boilers:

-

Simplifying and speeding up the process of emptying the boiler

-

Lifting and turning of the boiler without physical force

-

Increased operator safety

-

Minimising the risk of spillage and raw material losses

-

Electronic control via control panel

-

Compliance with occupational health and safety regulations

Thanks to the tippers for the boilers of the confectionery beaters, the production process becomes faster, more ergonomic and safer, making it an indispensable piece of equipment in any professional confectionery, bakery or food processing plant.