Cyclothermic ovens

Take your bakery to the next level with the Bagmasz cyclothermic oven, which combines rapid heating speed with perfect temperature control. Each baked product gains the perfect texture, crispness and flavour, even with a variable production range. Our equipment allows you to efficiently manage short and varied batches of baked goods, saving time and energy. Robust construction and reliable components ensure trouble-free operation for many years, minimising the risk of failure. Invest in an oven that allows you to increase productivity and enhance the quality of your baked goods - check out our range!

Product description

We encourage you to take a look at our range of cyclothermic furnaces. The equipment is dedicated to the baking of wheat, rye and mixed breads and small products in the bakery and confectionery segment. The manufacturer's many years of experience translates into many installations in Europe, Asia, Africa and the Americas.

How do cyclothermic ovens work?

Cyclothermic ovens are shelf ovens in which the baking chambers are heated by the continuous circulation of hot air around the baking chambers. This type of heating provides great operational flexibility: the oven is able to achieve the desired baking temperature very quickly.

As the cyclothermic oven weighs several times less than the ceramic-tube oven, it does not have as much heat accumulation capacity, which, with baking carried out at different temperatures, can be its an advantage.

How do you heat a cyclothermic oven?

The cooker can be fired by a gas burner, oil burner or pellet burner.

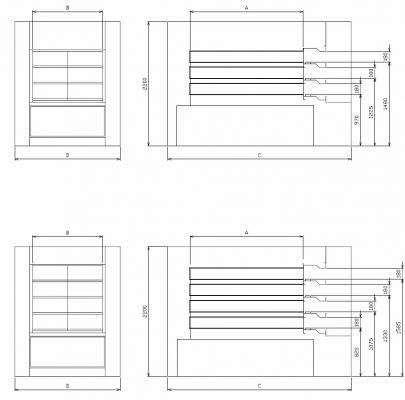

Cyclothermic furnace design.

The main components of the cooker are:

- heat exchanger with burner installed,

- turbines that distribute heat from the heat exchanger to all chambers,

- baking chambers,

- cooker housing.

What should be borne in mind?

Whether purchasing a cyclothermic oven or other ovens, Bagmasz provides all the necessary accessories, such as:

- tanneries,

- loading apparatus with trolleys

- loading system

Guarantee and financing.

- all the cookers we sell come with a 12-month guarantee.

- we offer assistance with financing through leasing companies and other forms of payment.

Why purchase a cyclothermic oven?

Cyclothermic ovens work well for short and varied baking batches.

What are the advantages of cyclothermic heating?

Cyclothermic heating provides very fast achievement of the set temperatureThis significantly reduces the oven's set-up time. Thanks to the circulation of hot air, the heat is evenly distributed throughout the baking chambers, which translates into a reproducible quality of baked goods regardless of production batch.

An important advantage is also low kiln weight compared to ceramic-tube kilns. The lower thermal inertia means that the oven responds more quickly to changes in temperature settings, which is crucial when baking in different temperature ranges within a single production day.

Cyclothermic ovens are valued for their high working flexibilityespecially in plants with a varied product range. The ability to change baking parameters quickly allows both short and more intensive production runs to be carried out efficiently, without any loss of quality.

It is also worth highlighting versatility of power supply - The oven can be fired by a gas, oil or pellet burner. This solution makes it possible to match the energy source to the current operating costs and fuel availability, which translates into real savings in the daily operation of the bakery.

Why purchase a cyclothermic oven?

Purchase of a cyclothermic furnace in Bagmash, is a guarantee robust and reliable technology. Robust components such as the heat exchanger, turbines and casing minimise the risk of failure, resulting in a trouble-free working and time-saving.

In addition, the cyclothermic ovens offered by Bagmasz make it possible to multiple power sources (gas, oil, pellets), which makes it possible to matching operating costs to bakery capacity and increases the profitability of the investment.

How do you look after a cyclothermic oven?

Systematic technical inspections make it possible to detect possible wear and tear on components early on and prevent costly production downtime. No less important is regular bakery machinery servicewhich includes not only inspections, but also repairs, maintenance, replacement of parts and adjustments. Using a professional service ensures that the cyclothermic furnace will operate reliably for many years.

The basis for the daily care of the device is regular cleaning of the baking chambers. Removing flour residues and crumbs prevents them from burning and maintains stable baking conditions. For this purpose, it is recommended to use special hoover for the ovenwhich allows the interior to be cleaned thoroughly and safely.

Maintenance of the components responsible for air circulation, such as turbines and circulation ducts, is also important. Their cleanliness ensures even heat distributionwhich has a direct impact on the quality of the baked goods and the energy efficiency of the oven.

Regular care, in accordance with the manufacturer's recommendations, ensures that the cyclothermic oven maintains its technical performance for many years. This is not only a way to reduce maintenance costs, but also to maintain a high production standard that end customers will appreciate.